Maintenance and tuc vehicles for monorail

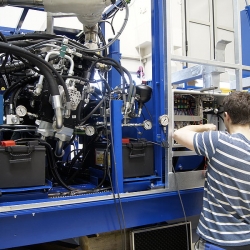

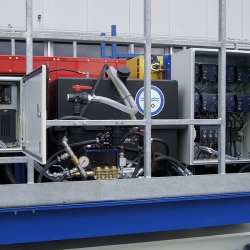

On behalf of a Swiss company operating in the sector of transportations, ATP Hydraulik has engineered the complete drive system for these monorail vehicles, including the hydraulic and electrical parts. All hydraulic and electric assemblies are designed, manufactured, assembled and put into operation in-house by ATP Hydraulik. On-site commissionings by our technicians.

Some features to one of these MRVs:

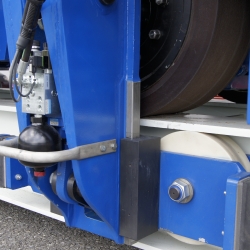

The drag force is max. 120'000 N. The drive wheels are pressed up to 100'000 N with hydraulic cylinders. Around 300 Lt. oil is in circulation. The wiring was realized with hoses up to DN40. Max. operating pressure is 420 bar.

The maintenance vehicle can move in both directions and without load with a speed of 15 km/h. The vehicle has a speed of max. 7 km/h when tugging the monorail train. A water pump which feeds track cleaning nozzles and four large brushes are built into the vehicle for cleaning the monorail track. The crane mounted on the vehicle can lift down a person to the same hight of the rail track.

The drive units are individually designed to the customers' requirements.

Learn more about this project in our detailled project description

Bologna, Italy

Ashgabat, Turkmenistan

Port Harcourt, Nigeria

Facts

Place: Bologna, Italy

Date: 2017

Place: Ashgabat, Turkmenistan

Monorail for the Olympic City

Project period: 7 months

Date: 2015

Place: Port Harcourt, Nigeria

Project period: 7 months

Date: 2013

Scope of delivery:

- Diesel engine with hydraulic pump unit

- Drive motors

- Brush motors

- Pressing cylinders

- Hydraulic drive with additional functions

- Electric operation and control system incl. software

Services:

- planning and design of the hydraulic system (engineering)

- construction and in-house production of the hydraulic assemblies

- planning and design of the electrical control system

- commissionings on site