Paving system for roundabouts

Project description

To build roundabouts and the construction machines for it demands high quality solutions. First, a short construction period is required, and second, to get roadways of highest quality.

With the paving finisher system for circles, asphalt and concrete surfaces can be made. An extremely efficient control system, with high precision and robust actuators allows a three-dimensional work. A new geooptical system enables the work without wire.

The traffic flow

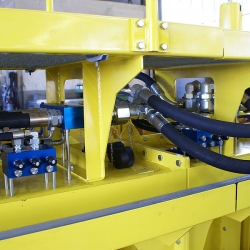

Nowadays the paving of roundabouts is very efficient and carried out within one day time. For the required adjustments and the desired drive options a hydraulics and electronics system is implemented into the paving machine. As roundabouts have varying diameters, the appropriate adjustments can easily be made by means of a hydraulic control system.

Technical features

The device can be extended as from 2.5 m up to 11.0 m and more paving width.

At a subdivision of 10 cm and at a variable layer thickness of a heigth of 5 - 35 cm.

The installation speed is at 0.30 m - 1.50 m / Min.

The inner radius of the roundabout construcion is > 5 m.

Geooptical control system

A geooptical control system with a connection to the hydraulic control system regulates the height, the direction and the cross slope of the paving machine.

Various parameters such as width and radius of the surfaces to be machined can be programmed.

A highly efficient computer and a control system with precise hydraulic adjusting units enables three-dimensional working of the paving machine.

Environmentally friendly operation

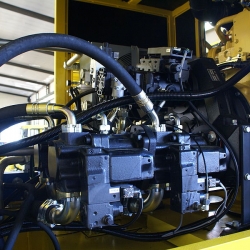

To ensure a safe and environmentally friendly operation, a diesel engine is chosen with emission control system, which is kept at a very low speed. Quad distribution gears, servo valves and axial piston pumps in open and closed circuits are relevant for the operation of the hydraulic actuators.

For each customer specific construction of paving machines and upgrades of existing machinery the complete hydraulic and electronic system can be planned, designed and constructed by ATP Hydraulik.

Challenges of this project: learn more about it in our detailled project description.

Facts

Place: mobile

Scope of delivery:

- Hydraulic drive with additional functions

- Hydraulic cylinders for steering and vertical adjustments

- Electric operation and control system incl. software

- Complete tubing and hosing