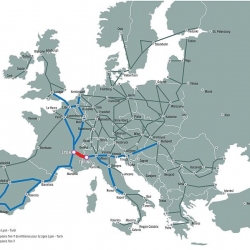

Logistic systems for tunnelling

Hydraulic and electric control systems for tunneling in use all across Europe.

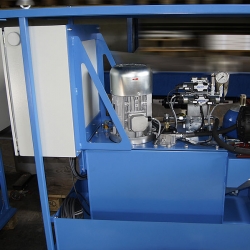

New system for water supply in Jerusalem

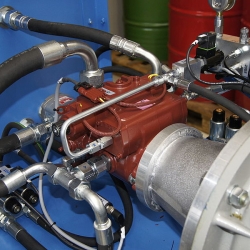

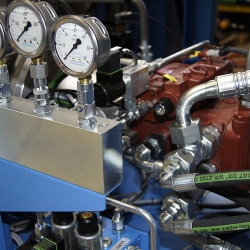

In Jerusalem, a new system for water supply will be ready in summer 2022. This water supply system will deliver desalinated seawater from the Mediterranean Sea to households and industry. For this project, a 13- kilometer tunnel had to be bored through the mountains of Jerusalem in order to lay the special water pipes. Shotcrete-coated steel pipes with a diameter of up to 4m were laid. This shotcrete coating was successfully implemented using the latest technologies, including the development of spraying robot, for which we developed the hydraulic system.

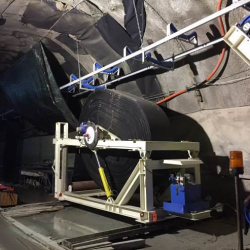

Citylink Stockholm (Anneberg - Skanstull Sweden)

There is an increasing demand for electricity in Stockholm. The new power connection Anneberg-Skanstull, between Danderyd and Hammarby Sjöstad, will secure the future electricity grid. At a length of around 14 km and a diameter of 5 m, the tunnel is being driven about 50 - 100 m below the Swedish capital using a tunnel boring machine. The rock masses are transported out of the mountain by means of a tunnel logistics system.

The film from Svenska kraftnät will tell you where, how and why they build this tunnel with electrical cables.

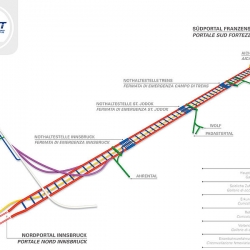

Brenner Base Tunnel (Austria - Italy)

The Brenner Base Tunnel is a horizontal railway line running through the Alps; a railway line for the future. The Brenner Base Tunnel is the main element of the new Brenner railway from Munich to Verona. At 64 km, it is the longest underground railway connection in the world, a pioneering work of engineering and it will markedly improve passenger travel and freight transport through the heart of Europe.

Lyon (France) - Turin (Italy)

On the new high-speed route between Lyon (France) and Turin (Italy) 1 million trucks and 40 to 50 million t of goods are set to be transported by rail annually from 2026 onwards. Constructing the new link between the two Alpine and Mediterranean countries will not only create the necessary capacities for the growing transportation of cargo by rail, but will also provide the required infrastructure for contemporary and ever longer cargo trains as well as the haulage of wide containers by the railways.

Facts

Place: Jerusalem, Israel

Date: 2022

Scope of delivery:

- Hydraulic unit for pressure oil supply

- The following functions are supplied by the power unit

- 3-section valve block for spray head drive (1x spray head tilt / 1x spray head bow drive / 1x spray head side drive)

- 4-section valve block for spray head - manipulation (2x swivel drive / 1x nutation / 1x lance drive)

Place: Citylink Stockholm, Sweden

Date: 2020

Scope of delivery:

- Hydraulic main drive of the conveyor facility

- Winches and clamping system for the operation of the conveyor facility

- Electrical control system and software

Place: Brenner Base Tunnel, AUT

Date: 2015

Scope of delivery:

- Hydraulic main drive of the conveyor facility

- Winches and clamping system for the operation of the conveyor facility

- Electrical control system and software

Place: Lyon-Turin, France-Italy

Date: 2016

Scope of delivery:

- Hydraulic main drive of the conveyor facility

- Winches and clamping system for the operation of the conveyor facility

- Booster power packs and booster cylinders for tensioning the conveyor facility system (16km)

- Electrical control system and software