Drilling rig for Crossrail London

About the project:

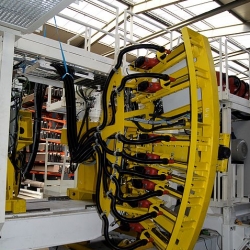

For a Swiss customer in tunnelling logistics ATP Hydraulik developed a drilling wagon for the new Underground in London (Project Crossrail).

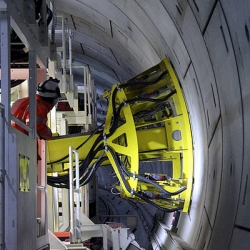

To replace the existing constructions and to expand the underground tunnel tubes for London.

37 Hilti drills and Hilti vacuum cleaners are mounted on the drilling wagon, which automated drill the mounting holes for the cable systems and cable trays inside the tunnel.

Both tunnel tubes were completely surveyed.

All drilling holes are recorded and we get a complete chart of each hole for each sector (every 6.4 meters) via USB. A log file records each hole and can be evaluated.

Commissioning of the unit by ATP Hydraulik.

Crossrail - to construct a network of new rail tunnels under London. From the East to the West, 42 km of new underground tunnels.

More facts: learn more in a detailled project description.

Press releases: in news

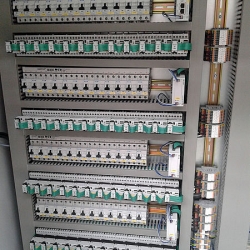

The electrical components included EATON’s SmartWire-DT® contactors and fuses for the drilling machines and pumps for the dust suppression system controlled via a Profinet/SmartWire-DT® gateway.

The SmartWire-DT® intelligent wiring and communication technology can help reduce machine wiring complexity by consolidating complex circuit wiring into a single, durable cable that can be connected to a standard network

Facts

Place: London

Date: 2015

Scope of delivery:

- planning and design of the hydraulic system

- construction and in-house production of the hydraulic assemblies

- planning and design of the electrical control system and software

- commissioning