Tube bending machine

Re-Design of a bending roll machine (plate rolls) for mechanical, hydraulic, electrical and software requirements.

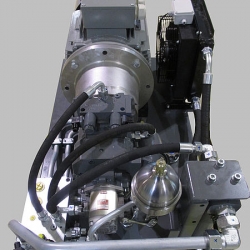

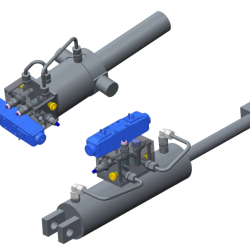

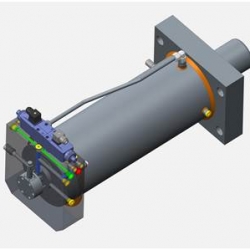

Pre-bending to the full rated capacity plate is accomplished with sufficient power in each side roll hydraulic cylinder.

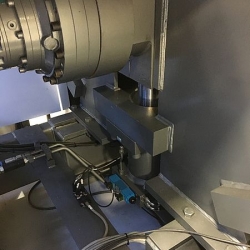

Rolls are easily adjusted on either end with an unique electronic leveling system.

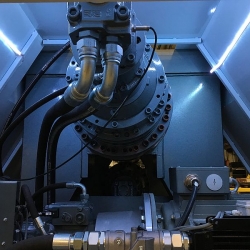

Spherical roller bearings increase drive’s efficiency by reducing friction.

Operator controls are located on moveable pendant or console for ease of use.

Variable speed differential achieved by the Independently Driven Top and Bottom Rolls, allowing them to seek their own speed when driving on the inner and outer radius.

Hydraulic cylinder actuates the automatic self-locking hinge.

Operator safety ensured by electrical disconnect with lock-out feature, e-stop button located on control, and a trip switch located along both sides of the machine.

Technical data:

Learn more in our detailled

Also visit the website of Bertsch, MegaFab Group, specialist for four roll, heavy-duty hydraulic bending rolls:

Running system

TEST-PHASE

MESSE FABTECH LAS VEGAS 2016

Facts

Place: Illinois USA

Date: 2016

Scope of delivery:

- engineering and structural design of the complete machine

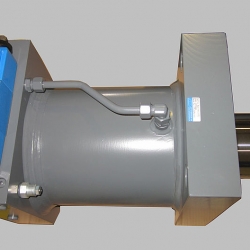

- hydraulic system

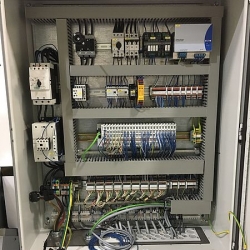

- electrical control system and software

- tubing, hosing, cabling

- engineering, manufacturing and in-house production of the hydraulic and electric assemblies

- commissioning on site